Lower Control Arm Extreme Joint Camaro Firebird 1982-2002

The control arm bushings found in the F-Body automobiles can have a significant impact on the vehicle’s ride, comfort, handling, acceleration, noise and vibration. When the car leans (i.e., rolls) in a turn, one side of the chassis moves upward relative to the rear axle, the other side moves downward, and the control arms must twist to allow for the axle to articulate. This causes the control arm bushings to bind. If this bind becomes excessive, it will raise the rear wheel rate and produce sudden, uncontrolled, undesirable changes in handling (e.g., snap oversteer). Chevrolet minimizes this suspension bind by using compliant rubber bushings in both lower control arms. These relatively “soft” bushings help accommodate the necessary motion of the control arms during body roll. However, the rubber bushings do not provide much in the way of forward and aft support, which can cause wheel hop during hard acceleration and braking.

It has become common practice to replace the stock rubber control arm bushings with solid or two piece polyurethane bushings to resolve the shortcomings of the soft rubber bushings. Hard polyurethane bushings eliminate wheel hop, reduce axle deflection, and improve rear straight line grip. However, the downside of common aftermarket bushings such as delrin, steel, stiffer rubber, solid or two piece polyurethane bushings is they prevent the necessary movement of the control arms during body roll, which in turn produces significant binding in the suspension when the vehicle is cornering. The polyurethane bushings also place unnecessary high stresses on the torque boxes, which are the attachment points for the control arms to the chassis. Standard aftermarket control arms do not allow for rotation of the control arm during cornering because of the stiffness of the bushings.

Solving The Problem:

Founders Performance LLC designed and built a tubular lower control arm which will eliminate the unwanted uncontrolled control arm flex. Round tubing is harder to work with but has many other advantages over square or rectangular tubing. It is stronger in bending, torsion, and also lighter than square or rectangular tubing.

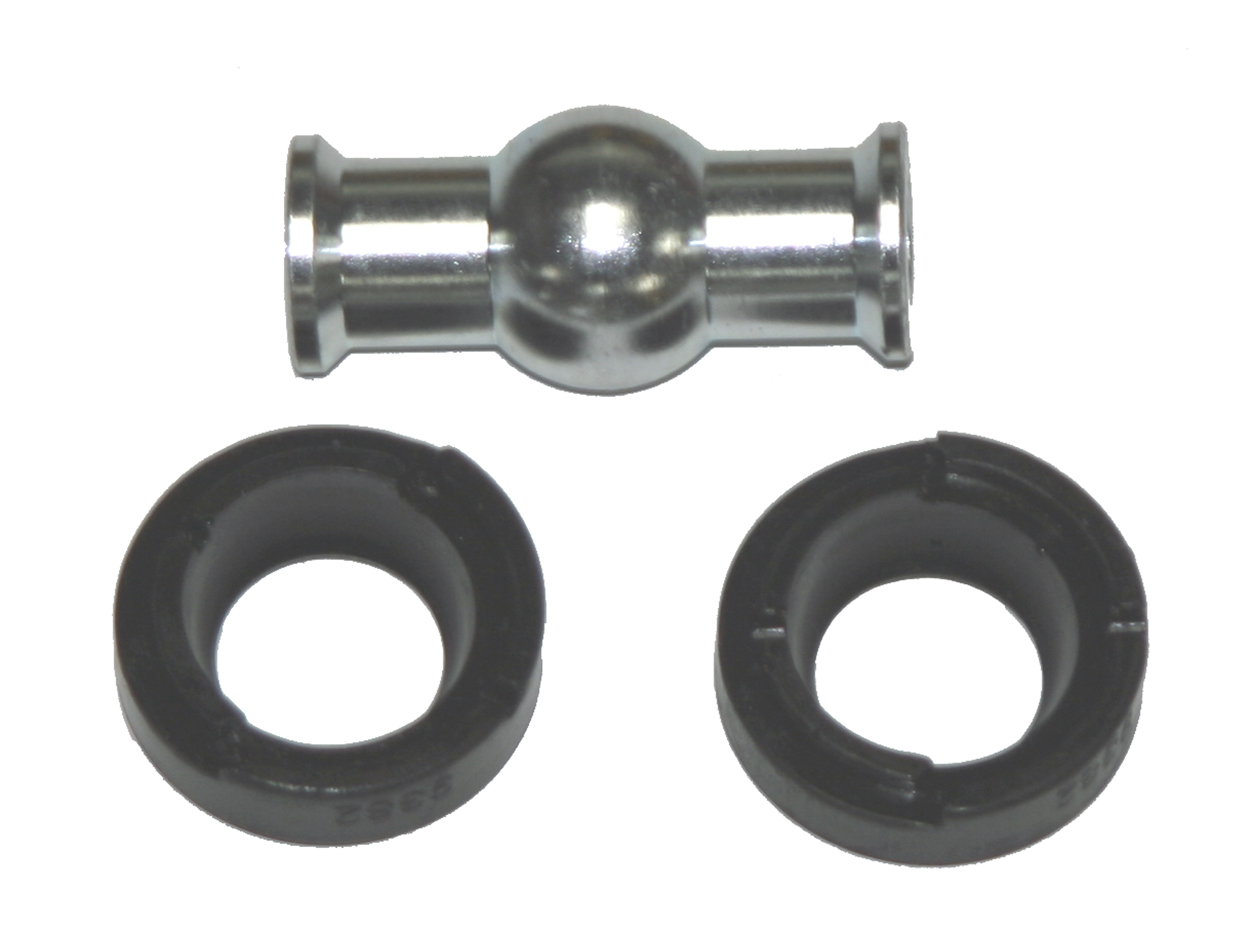

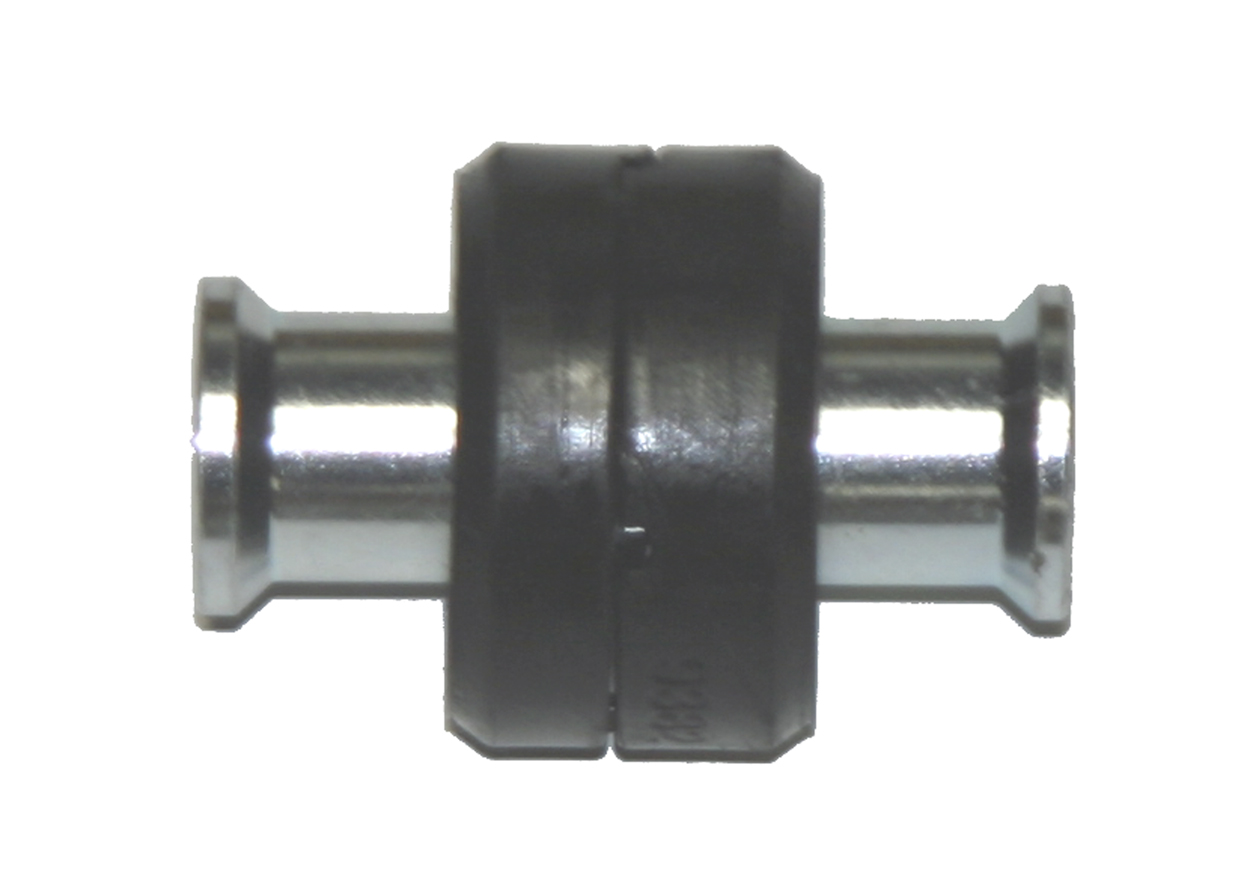

We then solved the shortcomings of the factory rubber and other aftermarket polyurethane and stiffer rubber bushings. This was accomplished with our new Swivel-Joint. By spending numerour hours looking and dissecting the geometry and the need of the rear suspension we come out with this bind-free bushings set up. Our Swivel-Joint bushing design incorporates a steel inner ball which is surrounded by hard polyurethane outer cups. This combination allows the bushing to articulate like a spherical bearing during cornering but the steel inner ball does not allow the bushing to deflect during acceleration giving you great traction during acceleration like solid bushings but remains completely bind free like a spherical bearing during cornering for great predictable traction in the corners.

Extreme Joint Camaro Firebird Features:

- 1.75″ Diameter High Strength Steel Tubing

- High frequency pulse spray welded superior strength

- Synthetic Elasomer greasable bushings on one end

- Swivel-Joing bind free bushing design on the other side.

- Installed grease fittings for on the car maintenance.

- Standard Red or Black powder coating for a great looking long lasting finish

- A necessity for any performance minded builder

- Improves responsiveness and control

- 100% MADE IN THE USA

Fits: 1982, 1983, 1984, 1985, 1986, 1987, 1988, 1989, 1990, 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002 Camaro and Firebird

For questions on this item please email us directly at sales@foundersperformance.com